Testing and repairing mechatronic systems are critical steps in ensuring the reliability, functionality, and longevity of products. The process involves a series of structured activities designed to identify and correct problems that may arise during production or operation.

1. Testing

- Functional Testing:

- Objective: Verify that each component and the entire system operates according to specifications.

- Methods: Use test benches and simulators to replicate operating conditions.

- Instruments: Multimeters, oscilloscopes, signal generators, logic analyzers.

- Electrical Testing:

- Objective: Verify the integrity of electrical circuits and components.

- Methods: Test continuity, resistance, capacitance, and signal integrity.

- Instruments: Multimeters, LCR meters, automated test equipment (ATE).

2. Repair

- Fault diagnosis:

- Objective: Identify the root cause of a malfunction or failure.

- Methods: Use diagnostic tools and techniques to analyze symptoms and locate faults.

- Tools: Diagnostic software, oscilloscopes, multimeters, signal analyzers.

- Component replacement:

- Objective: Replace defective components with new or refurbished components.

- Methods: Identify and procure replacement parts, follow proper handling and installation procedures.

- Tools: Soldering stations, desoldering tools, component testers.

- Circuit repair:

- Objective: Repair or rework printed circuit boards (PCBs).

- Methods: Repair solder joints, replace damaged traces, or replace defective components.

- Tools: Rework stations, heat guns, microscopes.

- Software reprogramming:

- Objective: Update or correct software problems.

- Methods: Flash new firmware, update software versions, or fix bugs in code.

- Tools: Programming devices, IDEs, firmware update tools.

- Mechanical repair:

- Objective: Fix mechanical failures or wear.

- Methods: Replace worn parts, realign components, or reinforce structural elements.

- Tools: Mechanical tools, alignment gauges, adhesives.

TESTING AND REPAIR SERVICE

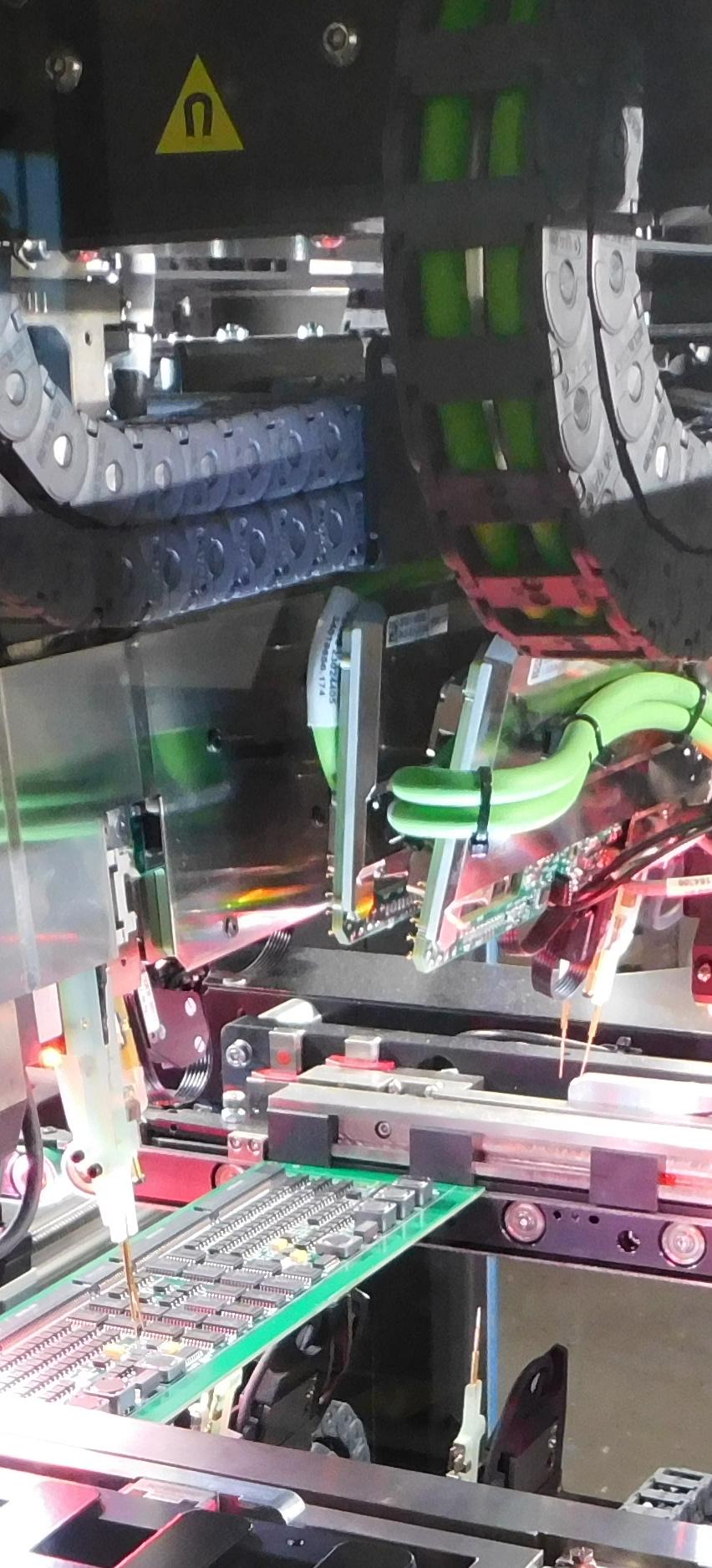

- Flying probe testing using SPEA systems, for reliable assembly components problem detection

- 3D X-ray analysis and tomography for assembly control of hidden components

- BGA/QFN rework using ERSA equipment

- BGA reballing service

- Manual repair of highly complex boards

Challenges and Considerations

- Complexity:

Manage the integration of multiple disciplines (mechanical, electrical, software) in testing and repair. - Accuracy:

Ensure accurate diagnoses and repairs to maintain system reliability. - Time and Cost:

Balance thorough testing and repairs with cost and time constraints. - Safety:

Maintain safety standards during testing and repair operations. - Documentation:

Maintain detailed records of test procedures, results, and repair activities for quality control and traceability.