FOR ELECTRONIC INDUSTRY

Call: +39 0323 287750 / 0323 346235 – info@mechatronyx.it

Call: +39 0323 287750 / 346235 – info@mechatronyx.it

WHAT WE DO

SERVICE SOLUTIONS

TESTING & PROTOTYPING

Our fast services

MECHATRONYX boasts over 20 years of experience in the electronics sector. Among the main services it is able to guarantee:

- Response to quote requests within 48 hours (feasibility studies, consultancy, processing of preliminary files by the customer)

- Engineering & Board design

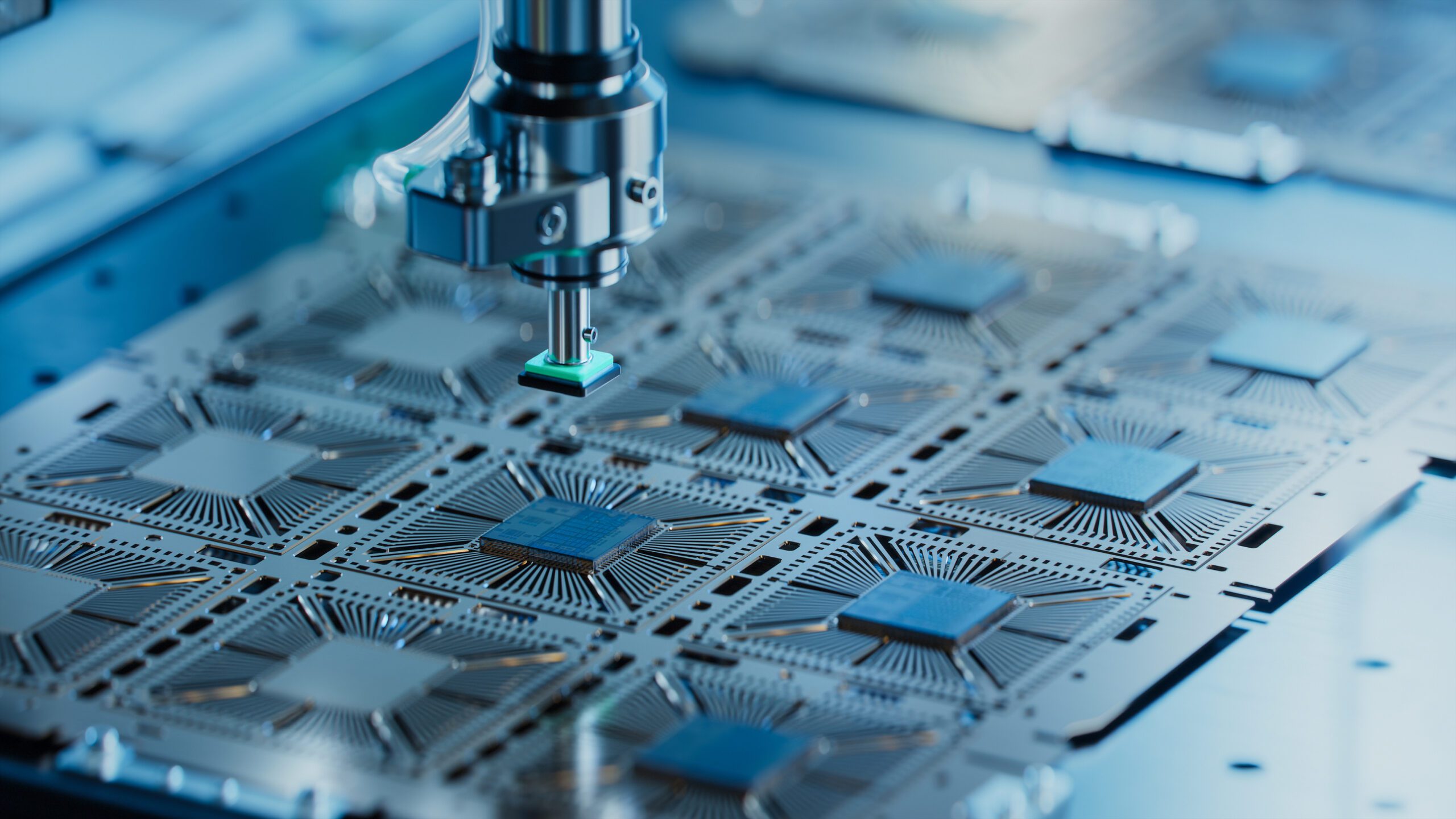

- PCB manufacturing and assembly of medium/high complexity prototypes in 48-72 hours

- Assembly of small and medium series in 1-2 weeks

- Absolute flexibility: Mechatronyx offers customer service 365 days a year

- 100% traceability of each product through the implementation of a company MES system

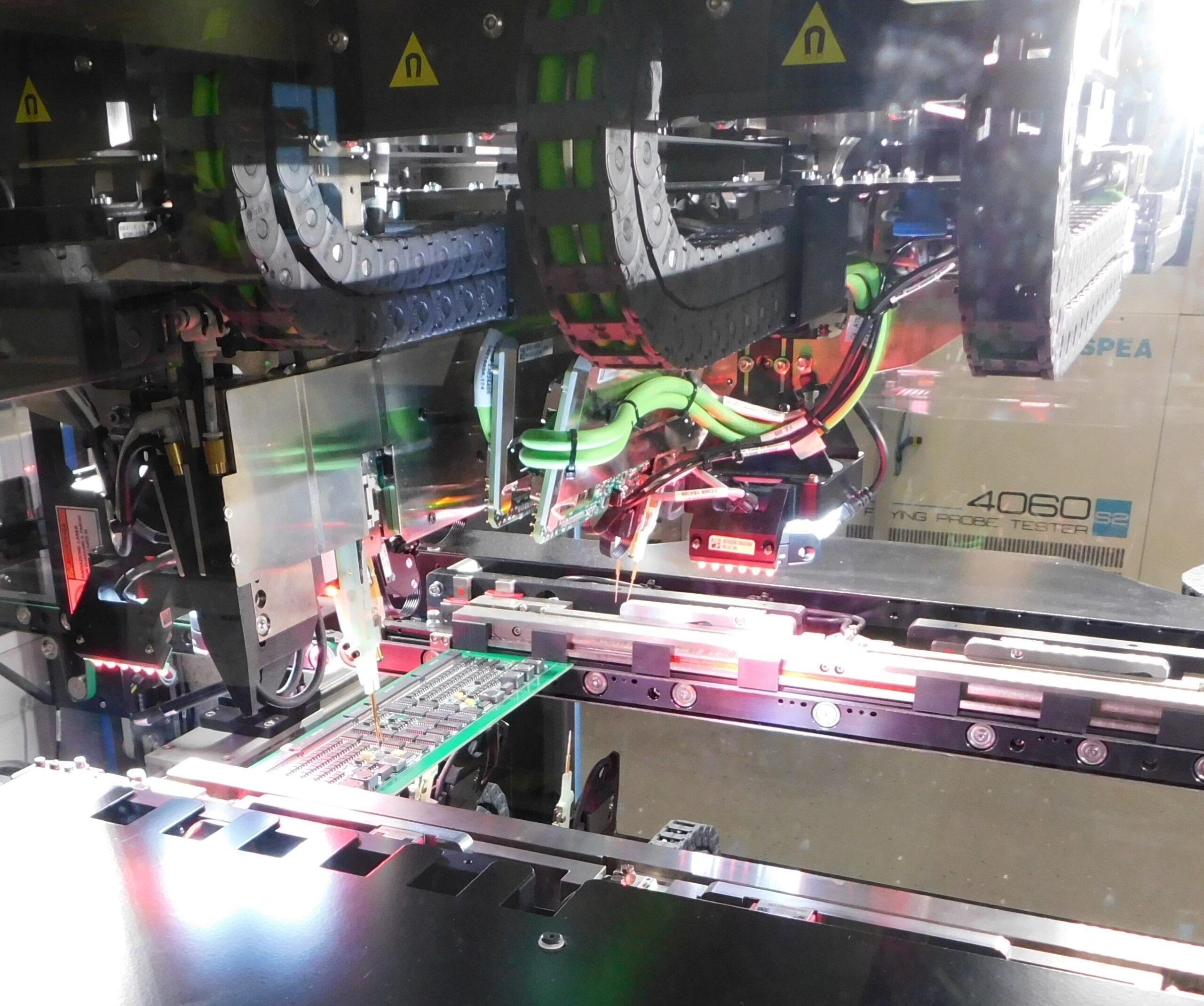

BOARD TESTING

Over the last 5 years, MECHATRONYX has invested huge resources for the development of test techniques and electronic cards

With the implementation of innovative latest generation machines dedicated to optical inspection (AOI) and ICT testing (Flying probe SPEA).

MECHATRONYX is able to guarantee:

- Over 99% yield guaranteed on boards assembled internally

- Test Services (AOI, ICT, X-RAY) of board on behalf of third parties

- Speed of service, in addition to the great efficiency and performance of latest generation machinery, an automatic loading and unloading system allows the machines to operate at 24h24 with remote control

- Flashing of microprocessor firmware via integrated OBP (On Board Programming) systems, functional tests and trials in general

- Detailed reports and documentation of the tested boards with the addition of targeted checks of highly critical PCB parts using high resolution X-ray scanners

OUR APPLICATION SECTORS

APPLICATION SECTORS

OUR SERVICES ARE AIMED AT A WIDE VARIETY OF MARKET SECTORS INTERNATIONALLY. HERE ARE JUST A FEW OF OUR AREAS OF INTEREST:

MECHATRONYX

OUR NEW MANUFACTURING PLANT

A NEW PRODUCTION UNIT, SPECIALIZED IN PRODUCTION OF SMALL-MEDIUM SERIES, WAS OPENED IN 2019 IN GRAVELLONA TOCE (VB).

ACCORDINGLY TO INDUSTRY 4.0 SPECIFICATIONS IN THE NEW PRODUCTION SECTION ARE INSTALLED NEW MACHINES OF THE LATEST GENERATION.

ABOUT COMPANY

PRODUCT SOLUTIONS

WE SPECIALIZE IN PROVIDE A SUPERIOR SERVICE AND RAPID ASSEMBLY OF PROTOTYPES IN ACCORDANCE WITH INDUSTRY 4.0 SPECIFICATIONS.