Production at MECHATRONYX S.r.l. involves small-medium production lots and pre-series, a series of integrated phases and processes that combine mechanics, electronics, information technology and automatic control to create complex and innovative products. Mechatronyx guarantees 100% traceability of production phases thanks to the implementation of an innovative MES system.

COMPONENTS SUPPLY AND SEARCH

- Safe vacuum packaging by automatic machine

- Supply of any type of component by purchasing worldwide at the

best conditions on the market with the highest quality assurance - Worldwide connection with larger component distributors and

specialized brokers for the search of critical components - Large amount of components in stock in our automatic

warehouse system, currently more than 15000 different items are available

(all stored in controlled humidity conditions <5%) - High level of quality control and related services:

- Precise counting by NORDSON Assure X-ray system

- Visual inspection

- 3D X-ray inspection by NORDSON system

- Disassembly and assembly service of components on sample

existing customer boards for electrical and functional tests - Baking service by automatic drying cabinet

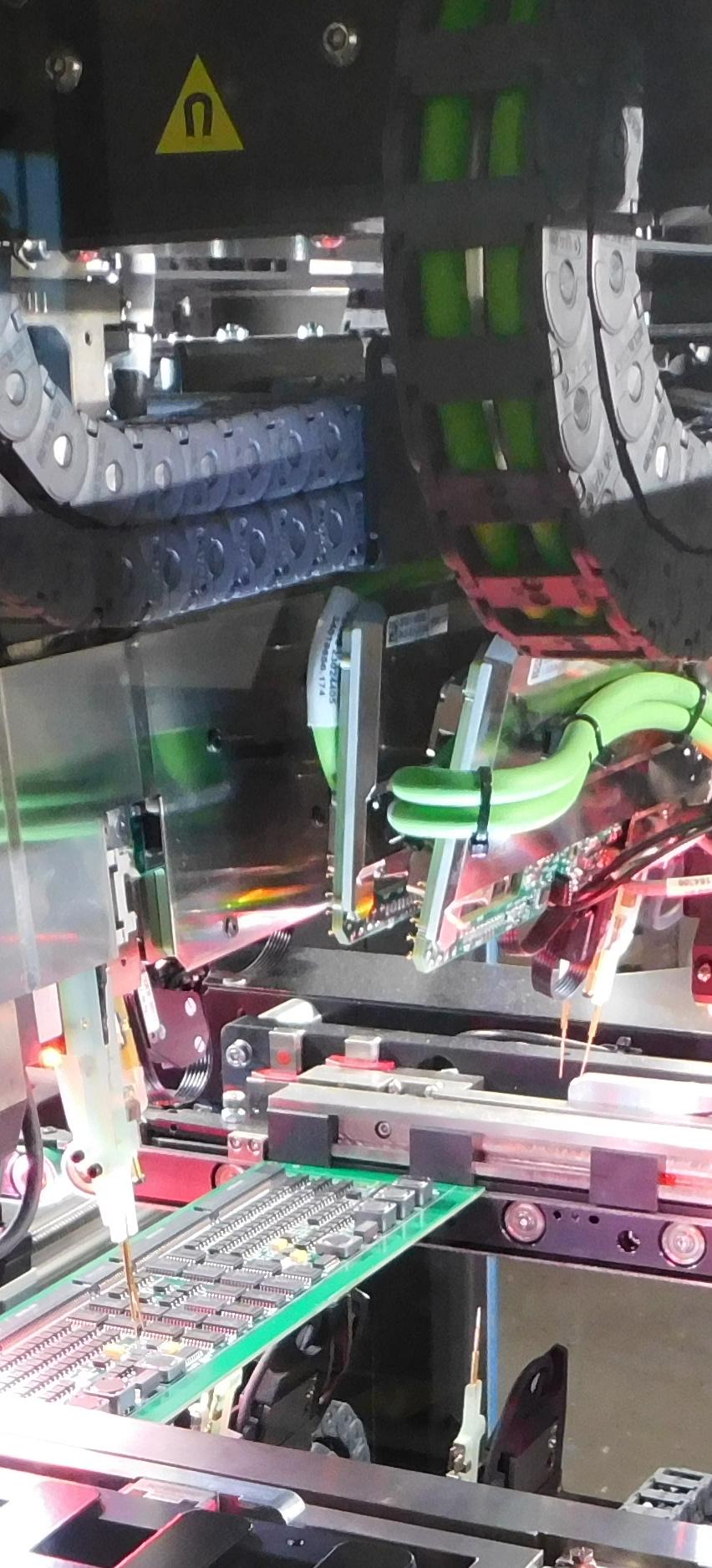

PRODUCTION PHASES

Pre-series-medium batch assembly: small production batches prior to mass production.

Materials Purchase: Management of the supply of the necessary materials and components.

Assembly: Assembly of the mechanical and electronic components in the production line using the best techniques and technologies, jetprint for the paste deposit, two types of ovens based on the needs (Vaphor Phase oven and heat zone oven)

Quality Control: Rigorous tests to ensure that each product meets the quality and performance standards. In addition to two Yamaha AOIs and 3 SPEA Flying Probes for TESTING, Mechatronyx is equipped with an in-line Yamaha AOI to monitor the process and avoid assembly errors.

- Integration and Testing:

System Integration: Combination of the various subsystems into a single working system.

Final Testing: Complete tests to verify the functionality, reliability and performance of the finished product. - Distribution:

Packaging: Preparation of the products for shipping, with adequate packaging materials.

Logistics: Management of product distribution to end customers.

BENEFITS

- Customization: Ability to create solutions tailored to specific customer needs.

- Innovation: Integration of advanced technologies to create cutting-edge products.

- Efficiency: Optimization of production processes to reduce costs and improve delivery times.

- Quality: Strict quality controls to ensure product reliability and performance.